Stainless Steel Welded Tubes

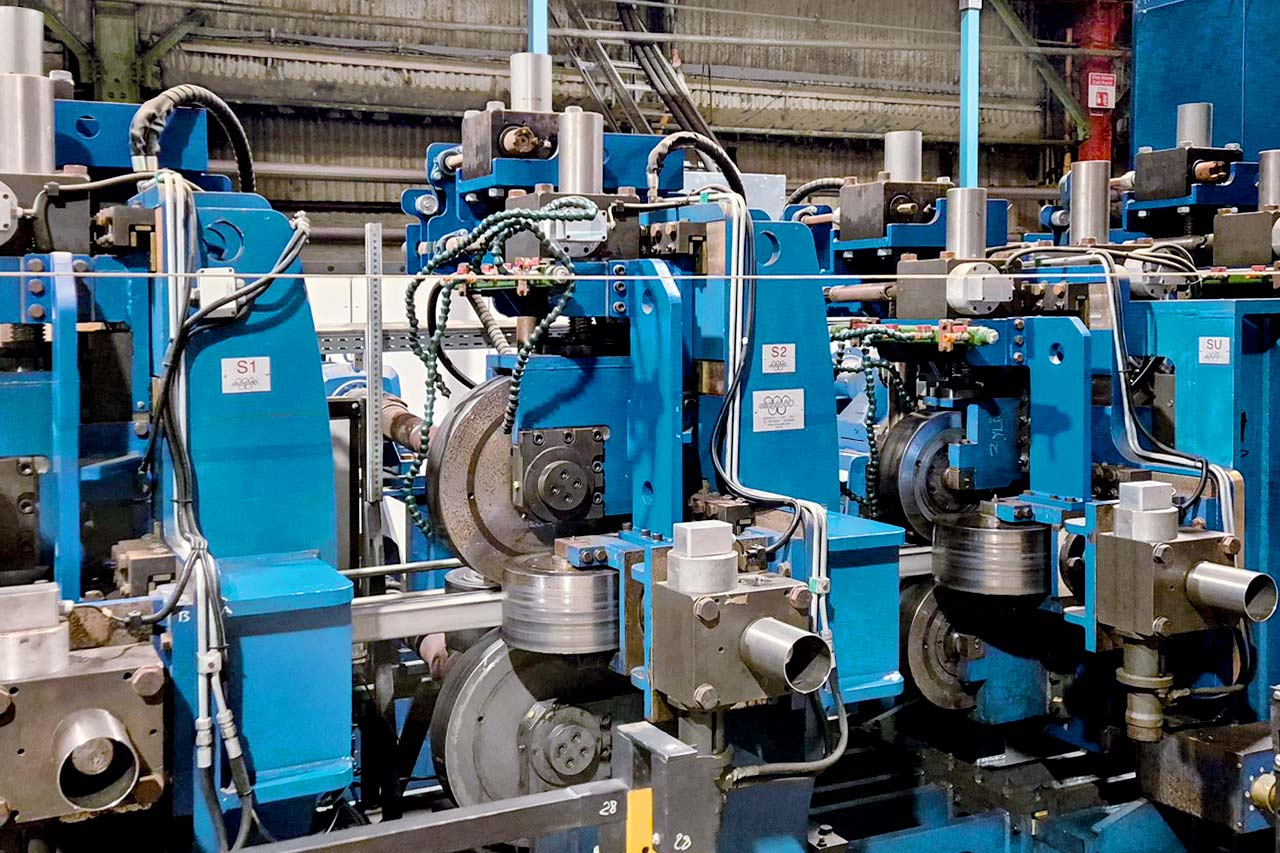

Marcegaglia is the world’s top producer of stainless steel welded tubes: stainess steel process pipes for food & dairy industry, tubes for heat exchangers and oil & gas, but also construction and ornamental tubes and box sections, as well as tubes for mechanical and automotive applications.

The fabrication process is carried out within 5 manufacturing units worldwide, guaranteeing the same quality levels of products.

Marcegaglia UK production of stainless steel welded tubes is in steel grade 304, according to EN10296-2 (for round tubes) and ASTM A544 (for squares and rectangles) manufacturing standards.

| ROUNDED TUBES | |

| Min-Max. thickness (mm) | 0.5 – 6.0 |

| Min-Max. diameter (mm) | 10 – 50.8 |

| SQUARE TUBES | |

| Min-Max. thickness (mm) | 0.5 – 6.0 |

| Min-Max. ext. size (mm) | 10×10 – 120×120 |

| RECTANGULAR TUBES | |

| Min-Max. thickness (mm) | 0.5 – 6.0 |

| Min-Max. ext. size (mm) | 20×10 – 180×60 |

MANUFACTURING STANDARD - PRODUCT DESIGNATION

| Standard ASTM A544 |

Steel Grade 304 | Square and rectangular tubes |

| Standard EN10296-2 |

Steel Grade 304 | Round tubes |

MANUFACTURING STANDARD - PRODUCT DESIGNATION

| Standard ASTM A544 |

Steel Grade 304 | Square and rectangular tubes |

| Standard EN10296-2 |

Steel Grade 304 | Round tubes |

LENGTHS TOLERANCES

Marcegaglia can guarantee tight tolerances on tube in-line cutting: ±1 mm on standard lengths ranging from 2,000 to 12,500 mm.

OPTIONAL PROCESSING

- Suitability for subsequent galvanizing

- Bead rolling

- Special end finishing

- Cut to length

- Customer defined marking

- Restricted tolerances

- Welding position

- Specific corrosion protection

- Specific packaging method

- Unit testing composed of tubes from a single casting

- Hot galvanization

STANDARD AND OPTIONAL TESTING

- Chemical composition

- Tensile test

- Flattening test

- Expansion test

- Impact test

- Non destructive weld test

- Dimensional test

- Micrographic analysis

- Visual test

- Surface roughness measurement

- Release of special certificates

SUPPLY CONDITIONS

- Dimensional tolerances according to manufacturing standard

- Special tolerances upon request

- Control documents 2.1, 2.2, 3.1, 3.2 according to EN 10204 and specific norm requirements